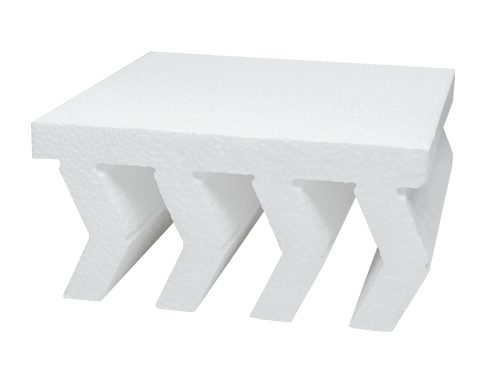

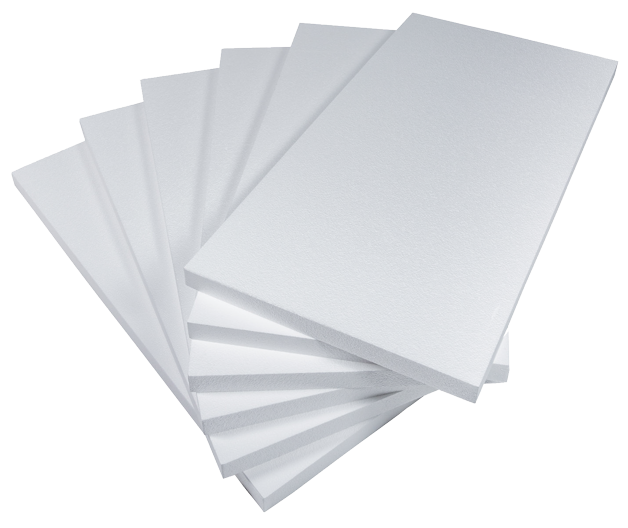

Introducing SuperForm EPS+, our high-grade expanded polystyrene (EPS) rigid foam insulation, a dependable solution for all your insulation needs. EPS insulation makes an excellent thermal insulator. Available in various forms, including EPS foam boards, sheets, and beads, it’s versatile and cost-effective.

Our SuperForm EPS+ takes this material to the next level, meeting the highest industry standards (CAN/ULC S701 and ASTM C578). It’s your insulation solution for various applications, embodying innovation, technology, and reliability.

Applications

Benefits of SuperForm EPS+

- Cost Effective

Impressive cost savings per R-value and Compressive Strength

Cost-Effective

SuperForm’s EPS+ delivers impressive cost savings, making it a budget-friendly choice for various applications. Builders and homeowners alike can benefit from its affordability without sacrificing quality. Its remarkable features ensure you get the most insulation value for your investment.

read more

- Stable – R-Value

Provides a stable R-value that does not deteriorate over time.

Stable R-Value Over Time

One of the primary concerns with insulation materials is their ability to maintain their R-value over time. SuperForm EPS+ excels in this aspect, providing a stable R-value that does not deteriorate over the years.

Unlike other materials, such as XPS, which may experience a reduction in R-value due to gas escape, Superform EPS+ stands as a reliable, long-term insulation solution. This stability ensures that your building retains energy efficiency and comfort for years. This also reduces the need for future renovations or replacements.

read more

- Compressive Strength

Available in 10, 16, 20, 25, 30, 40 and 60 psi

Versatile Compressive Strength Options

EPS+ has many compressive strength options catering to diverse construction needs. With options available at 10, 16, 20, 25, 30, 40, and 60 psi, builders can choose the strength that best suits their project requirements.

Whether you’re working on residential, commercial, or industrial projects, this versatility ensures that you have the ideal insulation at your disposal. This adaptability is a testament to SuperForm’s commitment to addressing the unique needs of every application.

read more

- Moisture Resistance

Closed cell polystyrene insulation proven to resist moisture gain.

Moisture Resistance

Moisture infiltration can be a significant concern in construction. EPS+ stands as a defense against this threat. Its closed-cell polystyrene structure is proven to resist moisture gain, ensuring your building remains dry and safe. What truly sets it apart is its rapid moisture release mechanism, allowing it to maintain its R-value over time.

Compared to XPS, which may trap moisture due to its low drying potential, EPS+ Insulation offers superior long-term protection. A 15-year study has shown that it absorbs a mere 5% water and retains 94% of its R-value.

read more

- Drying Potential

Designed to quickly release moisture and maintain its R-value. - Low Environmental Impact

Does not use or contain ozone-depleting blowing agents such as HFCs.Low Environmental Impact

EPS+ is manufactured with a pentane blowing agent, which has a drastically lower carbon footprint than the hydrofluorocarbons (HFCs) used in XPS production. It is also free of the harmful color dyes found in XPS.

By choosing SuperForm EPS+ Insulation, you’re making a sustainable choice that benefits your building and the environment.

read more

- Dimensional Availability

Options to suit every application – standards sizes or custom cut to your needs. - User Friendly

EPS+ is light in weight and very easy to cut and install.

Why Choose SuperForm EPS+

EPS+ vs. XPS Comparison

| EPS+ | XPS |

|---|---|

|

Cell Structure |

Cell Structure |

|

R-Value Stability |

R-Value Stability |

|

Long Term R Value: |

Long Term R Value: |

|

Compressive Strength |

Compressive Strength |

|

Cost |

Cost |

|

Water Absorption |

Water Absorption |

|

Water Resistance |

Water Resistance |

|

Vapor Permenance |

Vapor Permenance |

|

Environmental Impact |

Environmental Impact |

|

Dimensional Availability |

Dimensional Availability |

Customer & Partner Testimonials

“I’ve been building ICF houses between 25 and 30 years. This is one of the best technology inventions that has ever hit the building industry… I do have experience with 4 other brands of block and this is by far the strongest.”

Harvey CookIndependent SuperForm ICF Installer

“SuperForm was extremely easy to work with and they met all our target dates. Our project's actually a month ahead of schedule.”

Jason WhirfieldProject Manager, Kanas Corporation

“More than 20 years later, after what started off as single family residence that I still reside in today, we’re now beside an 18 story building built with similar [SuperForm ICF] techniques.”

Robert Sipka President, Kanas Corporation

“I have a 100% trust-based relationship [with SuperForm]. They care about their installers and they treat us right. My day is made better knowing that I’m not going to have to lug around 200 lb. forms; SuperForm is light and I feel like I can do it until I’m 60 or 70.”

Logan Dejax Revel Ventures

“When people ask me “Why SuperForm?” I can tell them out of out of experience, from just pumping other block, we don't have the success rate like we do with SuperForm.”

Brandon Elliott Edgecon Concrete Pumping

Choose SuperForm's EPS Insulation Solution

SuperForm EPS+ Insulation is the smart choice for building a sustainable, energy-efficient future. It offers superior insulation performance, cost-effectiveness, and environmental benefits. Choose EPS+ for your next building project and experience the difference.