Improving Construction With SuperForm MST-BAR

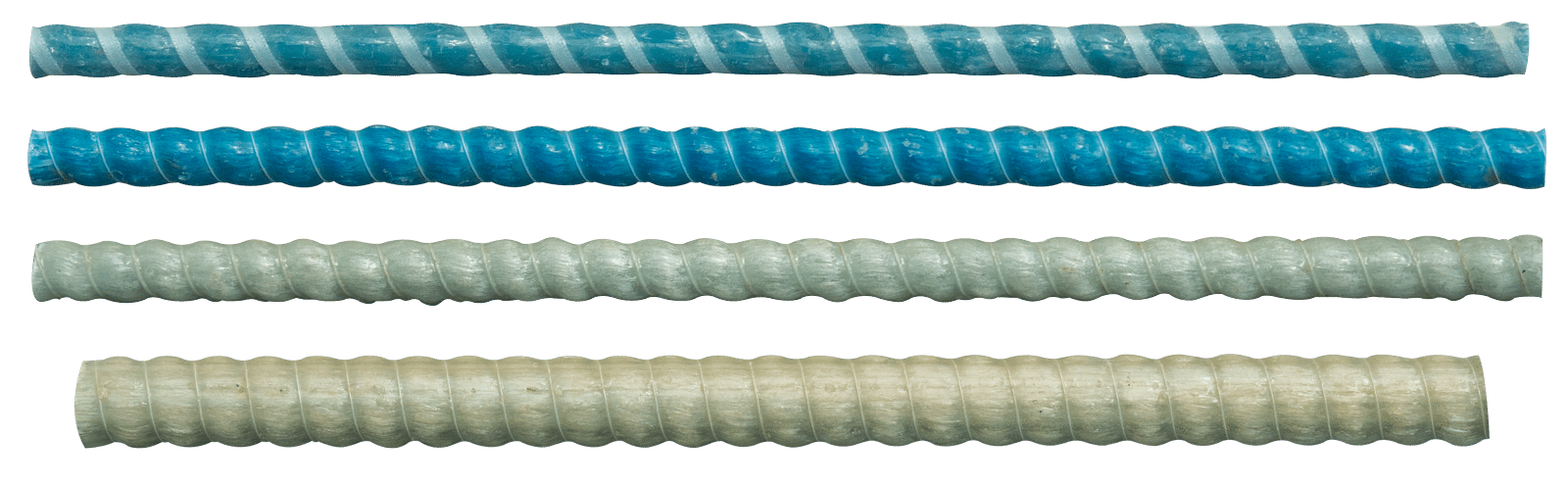

Introducing MST-BAR, a fiberglass rebar for use with SuperForm ICF. The glass fiber reinforced polymer (GFRP) material offers better tensile strength while being lighter than traditional steel rebar. With its unique properties and innovative design, it is redefining the standards for reinforcement in ICF blocks.

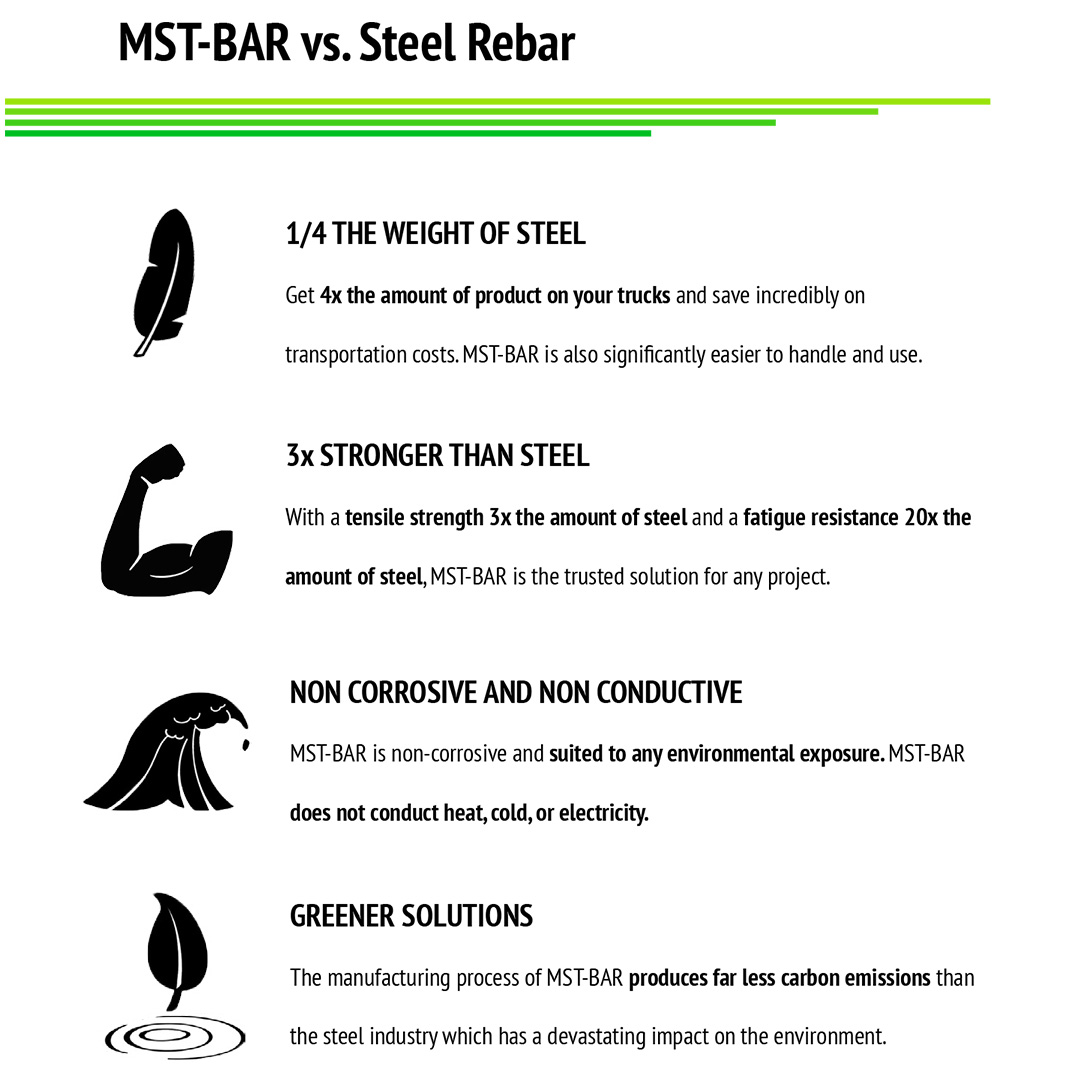

Our MST-BAR is changing the construction industry with its combination of strength and lightweight design. The GFRP material makes it much lighter than steel rebar, but it boasts a higher tensile strength. These features allow it to outperform traditional steel rebar in several ways.

With its impressive lightweight design, MST-BAR opens many possibilities for designers and builders. It is easier for workers to handle to help speed construction projects. However, you are not sacrificing strength when you go with this fiberglass rebar. It can handle the same construction applications while being easier to use and reducing costs.

The unique design of SuperForm’s rebar sets it apart from the competition. It's the only GFRP rebar featuring an integrally ribbed maximum strength design. This ribbed structure enhances its bond with concrete, reducing the risk of cracks.

It not only improves the structural integrity of blocks; it also allows for greater efficiency. Builders can also avoid up to 50% of traditional bent-bar applications using straight lengths of SuperForm MST-BAR.

We engineered our MST-BAR to be stronger, more reliable, and more cost-effective, setting new standards for performance and design.

Being stronger and lighter are just two of the reasons builders choose MST-BAR for reinforcing concrete blocks. The GFRP material and its innovative design improve performance in several ways.

MST-BAR forms stronger bonds with concrete, enhancing structural integrity and reducing the risk of cracks. It offers greater fatigue resistance, ensuring it can withstand more stress and provide enduring reinforcement.

MST-BAR is more than just a superior building product – it’s also more sustainable than the alternatives. The production of this fiberglass rebar results in lower carbon emissions than steel rebar. That means it has a lighter environmental footprint.

By choosing MST-BAR, you're not only building with strength and reliability, but you're also contributing to an eco-friendly future. It's the ideal reinforcement for builders who value sustainability as much as performance.

Why should I use MST-BAR for reinforcing concrete structures?

MST-Rebar is a fiberglass rebar that is specifically engineered and designed with an Integral Rib that mechanically locks it into concrete.

Unlike every other rebar, including traditional steel rebar and other fiberglass rebars, the only way to pull it out of the concrete is to break the concrete itself.

No other glass fiber reinforced polymer (GFRP) rebar, and certainly not steel rebar, can compete with MST-BAR's:

- 3x bond strength

- 3x tensile strength

- 20x fatigue resistance

MST-BAR is a more durable solution to concrete reinforcement.

Why do builders and contractors prefer it over steel rebar?

Builders and contractors are discovering the labor savings that come with the use of MST-BAR fiberglass rebar.

Specifically, MST-BAR is

- 4x lighter than steel

MST-Bar allows workers to install rebar with ease and reduce workplace injury.

Saving labor reduces the time builders and contractors are on each job site. The installation of MST-BAR fiberglass rebar:

- takes half the time to install with half the number of workers

- requires ZERO maintenance and repairs

Builders experience an increase in productivity with MST-BAR, allowing them to achieve more projects in a month or the same amount of projects.

What are the other benefits of MST-BAR over steel rebar?

Other benefits of MST-BAR over traditional steel rebar include

- Non Corrosive (suited to any environmental exposure)

- Non Conductive (does NOT conduct heat, cold, or electricity)

- Easy to Transport (75% lighter than steel, saving on shipping costs)

- Easy to Cut (especially when using a diamond blade)

"I worked all day hauling 10 piece bundles of 15M (#5) for our shop footings and still had energy at the end of the day... this is a large difference from how I feel after lugging 15M steel bar all day."

- Matthew Boese | SuperForm

"MST is better than steel because it is light, easy to cut, strong, and easy on the body."

-Logan | Riser Contracting

Where can MST-BAR be used?

Virtually anywhere you can use steel, you can use MST-BAR instead.

Applications of MST-BAR fiberglass rebar include but are not limited to:

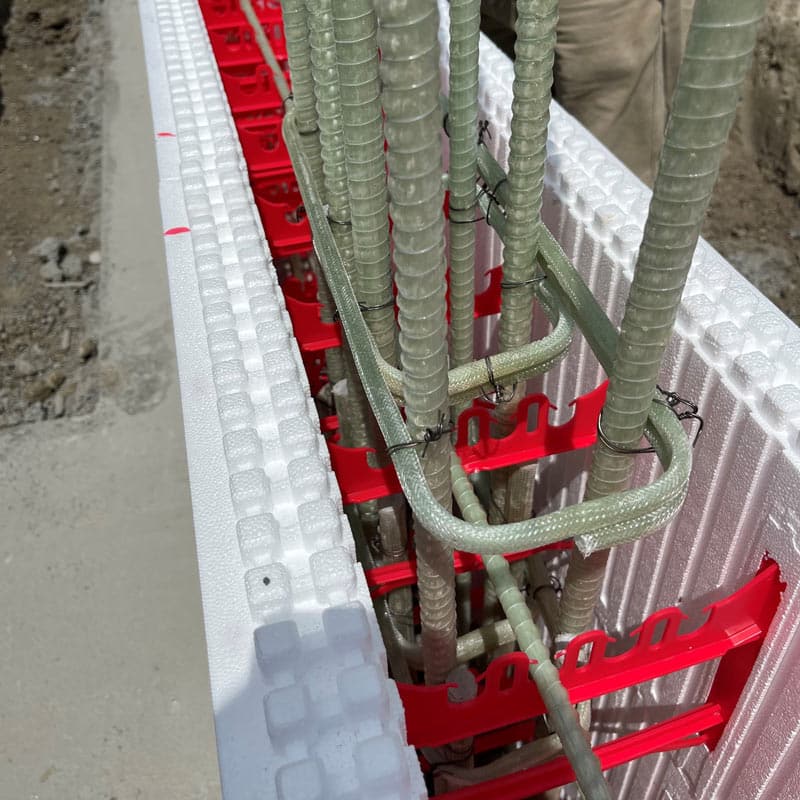

- ICF Walls

- Used for both horizontal and vertical reinforcement, MST-BAR is the best fiberglass rebar to use with our SuperForm Insulated Concrete Forms.

- The Integral Rib locks the concrete inside SuperForm ICF causing fewer cracks.

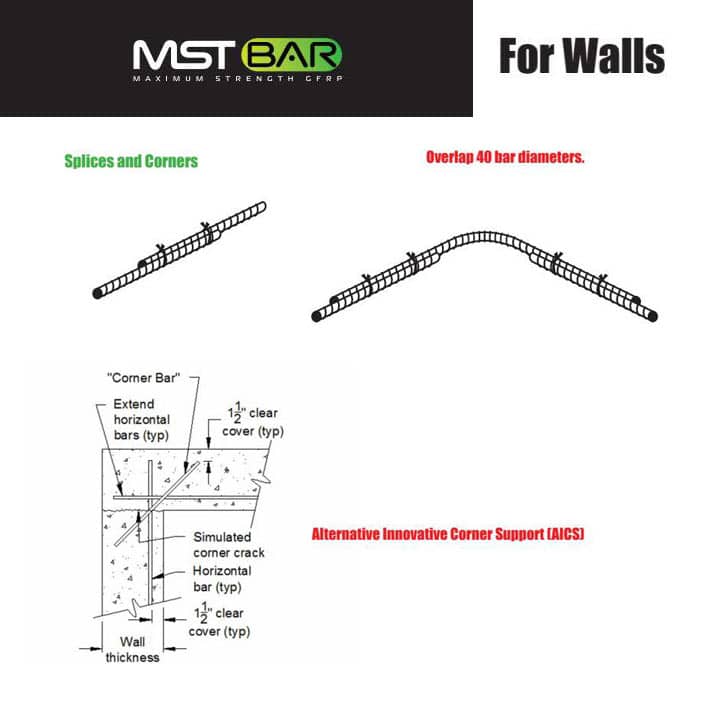

- MST-BAR's Alternative Innovative Corner Support method uses straight lengths of MST-BAR in the most vulnerable area of an ICF wall: the corner. This alternative method has been 3rd party tested and proven to provide a stronger corner than traditional bent bar applications. However, pre-bends of MST-BAR are available.

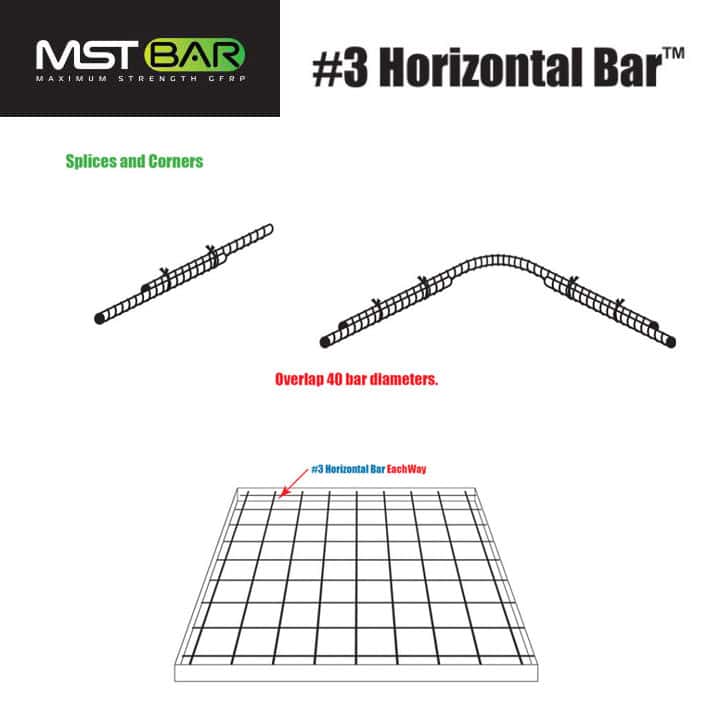

- Flatwork

- MST-BAR Grade I and Grade II are engineered for concrete flatwork.

- Whether it is a patio, driveway, or concrete slab, MST-BAR comes in diameters between 8mm - 10mm and is offered at lengths of 4ft - 60ft.

- Due to its non-conductive nature, no grounding is required.

Bar Sizes & Weight

CSA/ACI approved

All MST-BAR fiberglass rebar is in compliance with CSA S807 and ACI 440 codes including additional compliance and design codes.

Choose MST-BAR From SuperForm

SuperForm MST-BAR combines high performance with sustainability. Builders get a lighter, more versatile rebar while enjoying greater strength and corrosion resistance.

Choosing MST-BAR is a commitment to building better structures while being environmentally responsible. Reach out to SuperForm to learn more about our innovative building solutions.

Need more info about MST-BAR?

Visit our MST-BAR Product Knowledge Base to learn more about MST-BAR specs, the design manual for below-grade ICF walls, durability test results, and more.